Injection molding is a common manufacturing process. The principle involves heating and melting plastic pellets, then injecting them into a metal mold under high pressure. After cooling and solidification, the mold is opened to obtain the desired product.

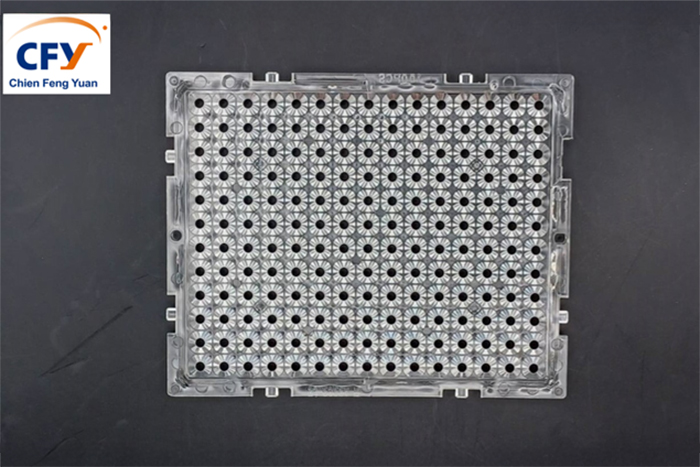

For example, in the case of optical tray carriers for lenses, ABS or PP is often used for injection molding due to their dimensional stability and smooth surface, which help prevent lens scratches during transportation. Another example is plastic components for LED lighting. Materials such as PC or PMMA are commonly used because of their high light transmittance and heat resistance, making them suitable for lampshades and lenses.

During the molding process, careful control of pressure and temperature is required to avoid flow marks or sink marks, ensuring that the final product has excellent optical performance and appearance quality.

The Relationship Between Trays and Plastic Injection Molding

In the optics, electronics, and semiconductor industries, trays are widely used for component carrying, handling, storage, and positioning in automated production processes. These trays are mostly manufactured using plastic injection molding technology for the following reasons:

1. High Manufacturing Efficiency

Injection molding is suitable for mass production, enabling the rapid manufacture of trays with consistent shapes and standardized specifications to meet the needs of automated production lines.

2. Dimensional Precision and Customizable Design

Injection molds can be precisely designed with holes and slots according to the product’s shape, size, and positioning requirements, ensuring that components remain stable and do not slide or collide during transportation and assembly.

3. Material Versatility

Common materials include:

PP, PE: Lightweight and cost-effective, suitable for general handling trays.

PS, ABS: High rigidity and excellent molding precision.

In addition, during the production and transportation of electronic and optical components, injection-molded plastic trays also play a critical role. These trays must not only provide good dimensional stability and durability but also incorporate electrostatic protection to prevent damage to sensitive components caused by electrostatic discharge (ESD).

Therefore, material selection often includes conductive or anti-static plastics such as conductive PP or PET-G. These materials effectively reduce surface resistance, achieving conductive or anti-static properties to ensure the safety of electronic chips, optical lenses, and sensors during handling and storage. At the same time, through injection molding technology, trays can be manufactured with high-precision structural designs, ensuring secure part positioning and improving overall production efficiency.

4. Durability and Reusability

Injection-molded trays offer excellent impact resistance and structural stability, making them reusable and helping to reduce packaging material costs.

5. Wide Range of Applications

These trays are widely used in fields such as:

- Optical components (e.g., lens carriers, LED lens trays)

- Chip/IC trays

- PCB and optoelectronic module positioning trays

- Testing trays for automotive lenses or sensor modules, and more.

The tray shown above is produced by Chien Feng Yuan and can be customized in specifications and appearance according to customer requirements. We provide a one-stop integrated service that covers mold development, prototyping, and mass production, with every stage overseen by our professional team.

With over 20 years of manufacturing experience, we leverage our extensive expertise and complete production system to help customers significantly shorten product design, development, and time-to-market, while effectively controlling manufacturing costs.